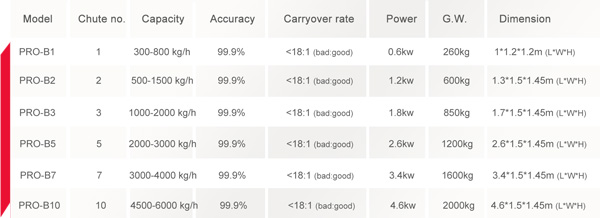

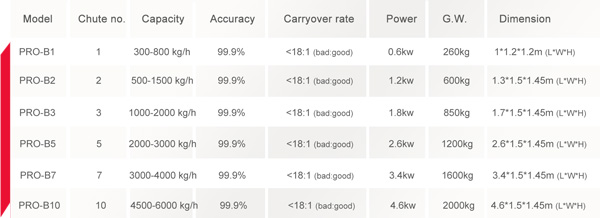

Model PRO-B3,with capacity 1000-2000 kg/hour

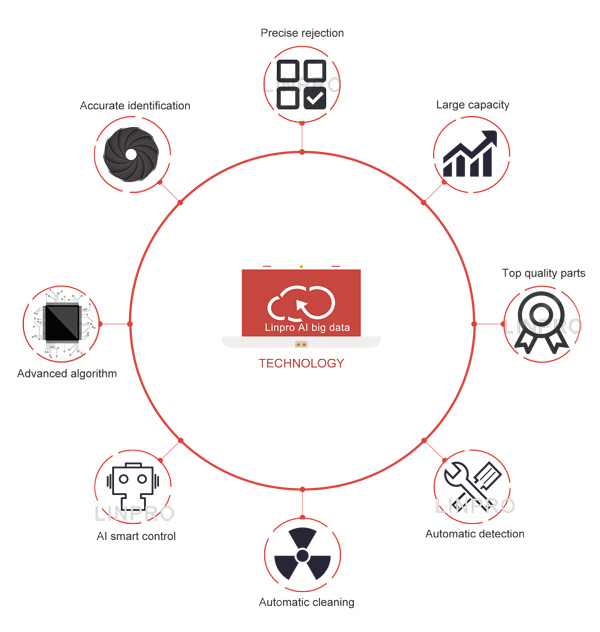

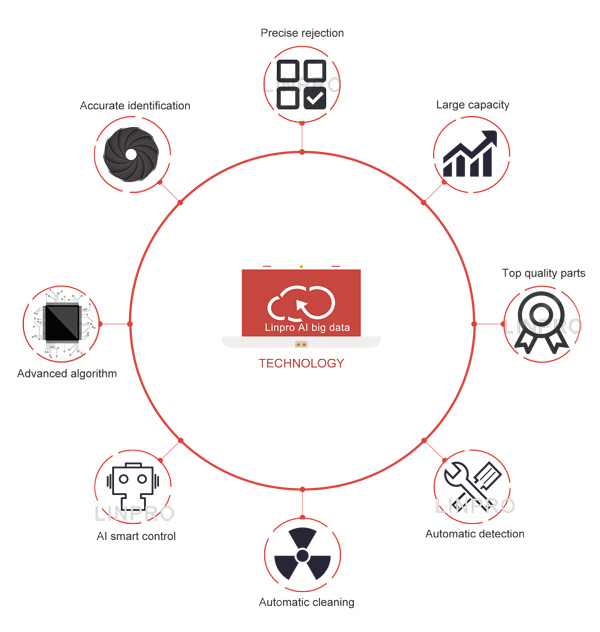

Color Sorter Function

LINPRO AI color sorter also performs very good to sorting massor dals, the defective massor dals are separated according to the color difference with good massor dals, through blowing the rejected massor dal out by high frenquency injector.

Technical Advantage of Massor Dal Color Sorter

We adopt highest level industrial parts, like CCD camera, high frequency injector, High-light LED, durable flow chutes, smart operation system, makes machine full automatic and easy used.

Massor Dal Color Sorter Details

Welcome to contact us for any questions about any model of the machine.

After sales service

We provide every customer our best machine, with thoughtful after sales service, please check below are the basic services:

1. We can send an engineer to set the machine well in local;

2. 1 year machine quality guarantee;

3. Software updated lifetime to enjoy LINPRO' s newest technology.

4. Free spare parts provided.

For service details, please check "Service" from "Solution".

Welcome to contact with us for any questions.

Technical details of Massor Dal Color Sorter

A high-speed, low-cost, image-based sorting device was developed to detect and separate grains with different colors/textures. The device directly combines a complementary metal-oxide-semiconductor (CMOS) color image sensor with a field-programmable gate array (FPGA) that was programmed to execute image processing in real-time without the need for an external computer. The spatial resolution of the imaging system is approximately 16 pixels/mm. The system utilizes the inherent parallel processing capabilities of FPGA's to inspect three separate streams of grain with a single camera/FPGA combination. Kernels are imaged immediately after dropping off the end of a chute and are diverted by activating an air valve. The system has a throughput rate of approximately 225 kernels/s overall, which is much higher than previously developed image inspection systems.

Linpro AI COLOR SORTER

Linpro AI COLOR SORTER